About the client:

A leading provider of semiconductor manufacturing tools, the client faced mounting technical debt due to mergers and acquisitions. Their software ecosystem had become fragmented, with multiple coding languages, outdated architectures, and siloed applications creating inefficiencies in automation and real-time hardware interactions.

To support a major product initiative in 2025, they needed a structured modernization strategy that preserved precision hardware communication while eliminating legacy constraints.

Benefits Overview:

60% Reduction in Manual Processes

40% Improvement in Application Performance

Challenge

The client’s software stack relied on VB6 and COM objects for core application logic and hardware communication, creating scalability and performance bottlenecks. Manual processes slowed down operations while existing automation lacked the flexibility needed for modern semiconductor manufacturing.

The modernization effort had to balance multiple priorities:

- Eliminating legacy dependencies while maintaining functional accuracy.

- Replacing VB6 components without disrupting real-time hardware interactions.

- Standardizing fragmented backend systems for better data management.

- Improving UI/UX by transitioning from Windows desktop applications to modern web-based frameworks.

- Ensuring high-precision motor control for stepper and servo systems, which required exact timing and synchronization.

- With six critical software components needing transformation, the challenge was to modernize seamlessly while preserving hardware precision and workflow continuity.

Solution Architecture:

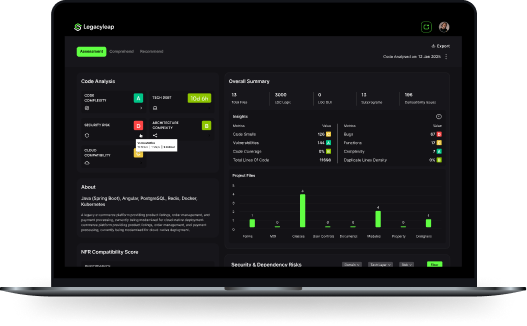

Legacyleap deployed a phased, AI-accelerated modernization strategy to revamp the client’s technology stack while ensuring uninterrupted operations.

The first step was decoupling COM object interactions, replacing them with modern microservices-based architectures to enhance scalability and interoperability. VB6 components were systematically rewritten in .NET, improving maintainability and real-time processing efficiency. This transition preserved core application logic while eliminating legacy constraints.

To address UI limitations, we migrated legacy Windows desktop applications to modern web-based frameworks, enhancing user experience and ensuring compatibility with future cloud-native applications. On the backend, Microsoft SQL Server optimization and selective cloud-native data processing improved database performance and streamlined workflows.

Given the need for precise stepper and servo motor control, we implemented real-time synchronization mechanisms, ensuring that hardware operations remained highly accurate. AI-powered test automation was introduced to validate system integrity across all modernized components, accelerating deployment while reducing manual effort.

By adopting a structured migration roadmap, we phased out outdated components while ensuring a seamless transition, minimizing disruptions and enabling long-term scalability.

Results:

50-70% Reduction in Manual Processes

Automation eliminated inefficiencies, streamlining workflows.

40% Improvement in Application Performance

Optimized backend interactions and modernized APIs enhanced system responsiveness.

Seamless Integration Across Ecosystem

Standardized architectures ensured compatibility with semiconductor manufacturing tools.

Precision Hardware Communication Maintained

Real-time processing accuracy was preserved with advanced synchronization mechanisms.